Carbolac

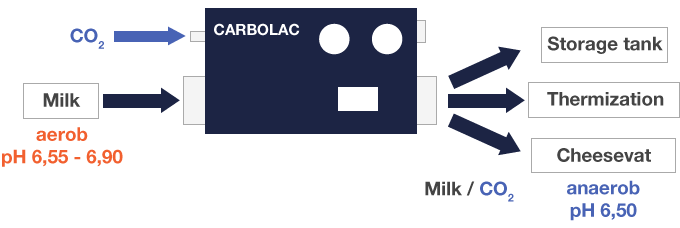

Quality improvement, cost reduction, and process security in cheese production through precise CO2 dosage into milk

Qualitative and Economic Optimization in Rennet Cheese Production

Carbon Dioxide CO2 is a natural ingredient of milk and cheese that features very interesting characteristics. Its application as an additive in cheese production is therefore highly effective and absolutely safe.

According to EU Guideline 95/2, Appendix 1, CO2 (E290) is permitted in the EU to be added to all foodstuffs as an additive without restriction. A labeling obligation does not currently exist for the dairy applications presented.

Cost reduction as a result of:

Less microbial or annimal rennet addition at lowered pH (ca. -30% at -0,1 pH, -40% at -0,2 pH), less culture application, less washing water.

More process safety as a result of:

Standardization, optimized pH value, higher anaerobicity (prevention of harmful germs), stabilized protein structures (CO2 binds as hydrogen carbonate to casein structures).

Shorter production times as a result of:

Shorter prerippening of cheese milk (protein swelling improved by CO2), more standardization – uniform production process in connection with the applicationof DVS cultures.

Quality improvement as a result of:

Less dry matter variation (< + 0.5%), increased syneresis, firmer texture in the product with uniform water content in connection with the application of DVS cultures.

The Carbolac technique can be applied to virtually all dairy facilities. It is compact, installation is easy and quickly done. Only a few prerequisites have to be taken into consideration.

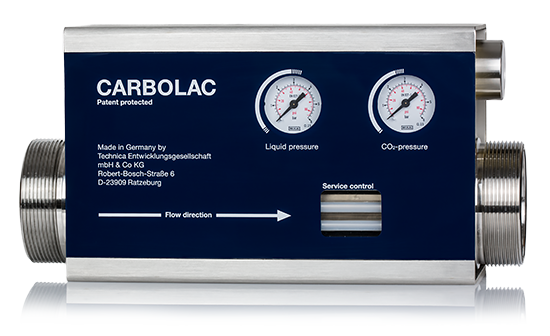

Carbolac Processor Technical Data

- Stainless steel design (1,4571)

- CO2 metering 0.05 to 4 g/l milk

- Preliminary gas pressure > 6.5 bar

- 3 levels of milk flow performance:

- M 10: up to 15 cbm/h

- M 60: up to 54 cbm/h

- M 80: up to 72 cbm/h

- Dimensions (H x W x L) 150 x 240 x 100 mm

- Weight acc. to performance 13 kg to 17 kg

- Milk pressure 1 bar to 10 bar

- Milk line connections as desired

- Inline metering with suction injector

- No electrical connection

- Remote control or automatic control as accessories

Carbolac Technique Benefits

- CIP-capable as standard feature, no hygiene considerations

- Fully automatic gas pressure regulation with safe on & off switching

- High quality due to gas metering proportionate to milk quantities

- Digital display of value setting

- Simple function and hygiene controls

- Compact design, flexible applicability

- Good price/performance ratio

- Economically improved by individual service concepts

Play it safe with:

- Proven, patent-protected technology

- competent technological advice and startup

- reliable service at all times