Carboflot

The Flotation Principle

The flotation process enables the effective separation of clear fluids and suspended particles. In this process a gas – air, nitrogen or oxygen – is inserted and dissolved into a fluid under pressure. When the pressure is removed, the gas is released in the form of fine bubbles that attach to the solid particles in the liquid.

The gas bubbles rise to the top in a flotation tank and take the particles with them, forming a solid particle layer on the surface. The clear fluid can then be removed from the bottom of the tank. Flotation can thus be considered the reverse of sedimentation, because the particles float to the top thanks to tiny air bubbles rather than sinking to the bottom.

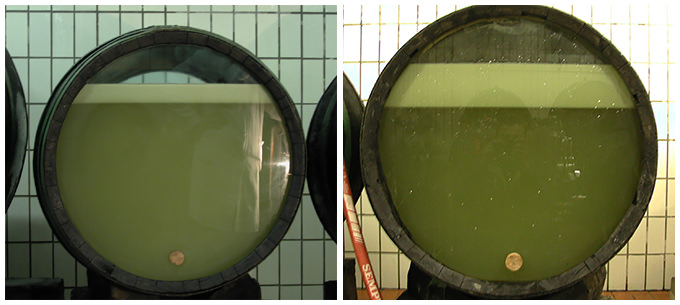

Left: Carboflot-System

Right: Other System

The particle layer becomes extremely compact thanks to the very fine micro-bubbles. Post-processing of the particles is therefore unnecessary, and the must yield is excellent as compared with other systems.

Quality improvement in wine

Reducing cloudy particles and phenols are major objectives of quality-oriented grape and must processing. The taste of the wine is dependent upon the remaining cloudy particles in processed must. The remaining cloudy particles should be less than 0.6 % by weight (according to J. Seckler of the Geisenheim research centre). This value can be reached easily with the Carboflot system. The most important quality benefits of must flotation are:

- excellent purity

- better colour

- fewer sulphide off-flavours

Advantages of the Carboflot system

The Carboflot system consists exclusively of high-quality system components that together create an optimal complete solution for efficient and effective primary must sedimentation. The compact and versatile systems are easy to use. Repeatable settings allow for consistent clarity. For example, gelatine can be dosed into the must stream via a microchip-controlled hose pump with an extra large adjustment range, which prevents partial under- and overdosing.

- premium system components

- flotation effect easy to check via the sample spigot

- easy to use

- Carboflot does not require supervision, as the system function is completely automated

- compact and versatile systems

- precise air and gelatine dosing

- fresh air dosing (no compressor, oil strainer, no active carbon filter)

- perfect complete solution: effective, flexible, powerful

Premium system components

- stainless steel frame on four wheels (2 castors with brakes)

- multi-level, high quality and CIP-capable stainless steel circulation pump (Hilge)

- electronically adjustable gelatine dosing pump with an extra large adjustment range (Watson – Marlow, IP55)

- stainless steel flotation tank with automatic de-airing and filtering option

- air injector dosing with automatic turnoff when the pump stops (the system can also be used with compressed air or nitrogen if needed)

- stainless steel spigot for taking samples and to check the flotation results

- exact needle valve regulation for air dosing with flow rate meter

- stainless steel disc valve with stainless steel shut off valve for control

- stainless steel switch case (all components: at least IP 55) 400 Volt/50Hz

- automatic flotation pump shut-off when operated dry

- automatic gelatine dosing shut-off when flotation pump stops

- flow rate and pressure display for must

- double wall gelatine reserve container for warming 200 L of gelatine (optional)

Technische Daten

| Installation type | Carboflot hl 75 | Carboflot hl 125 |

| Flow performance | ca. 2.000 – 7.500 l/h | ca. 5.000 – 12.500 l/h |

| Operating pressure | 5 – 8 bar | 5 – 8 bar |

| Dimensions | L 120 x B 65 x H 180cm | L 120 x B 80 x H 180cm |

| Weight | ca. 180 kg | ca. 190 kg |

| Connections | NW32 / NW 25 | NW50 / NW32 |

| Voltage | 400 V / 50 Hz | 400 V / 50 Hz |

| Protection type | IP 55 | IP 55 |

| Power consumption | ca. 4 KW | ca. 7,5 KW |

| Installation type | Carboflot hl 200 | Carboflot hl 275 |

| Flow performance | ca. 10.000 – 20.000 l/h | ca. 20.000 – 27.500 l/h |

| Operating pressure | 5 – 8 bar | 5 – 8 bar |

| Dimensions | L 120 x B 80 x H 180cm | L 120 x B 80 x H 180cm |

| Weight | ca. 230 kg | ca. 250 kg |

| Connections | NW50 / NW32 | 400 V / 50 Hz |

| Voltage | 400 V / 50 Hz | 400 V / 50 Hz |

| Protection type | IP 55 | IP 55 |

| Power consumption | ca. 11 KW | ca. 15 KW |