Carbomaxx

Simple carbonization of sparkling wine / beer / cider, etc.

Consistency is key in ensuring the high quality of beverages. This mostly pertains to precise carbonization of the product that ensures fine bubbles. The affordable and easy-to-use CARBOMAXX carbonator is normally used directly during the filling process. To add an exactly predefined amount of CO2, you enter the desired value via the touch panel. As soon as the product starts to flow, this amount will be automatically added proportionally to the flow rate. This ensures a reliable CO2 dosing even with highly fluctuating flow rates. The CIP-ready system can be used both in cellars and directly during the filling process and does not require a buffer tank. The beverage loss during the product exchange is thus reduced to a minimum. This mobile and compact system requires little space and is perfect for producing small to medium beverage quantities. Additionally, it can be easily integrated into every filling line and can also communicate with the filling or cooling system, etc. if necessary.

Numerous options that allow for example the measurement of the CO2 content or a second control unit for remote control perfectly round up the CARBOMAXX system.

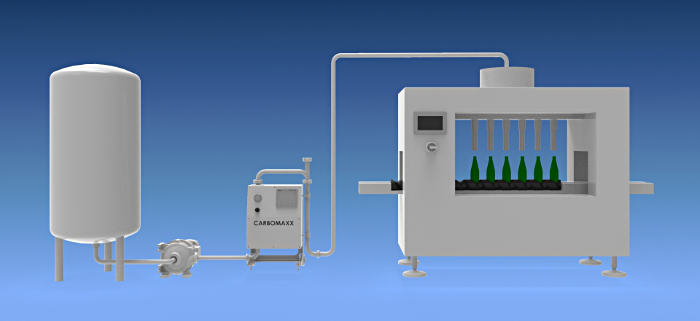

Typical installation conditions

Special features and advantages of CARBOMAXX

- Precise carbonization directly during the filling process without a buffer tank

- Flow rate optimized dosing

- Perfect fine bubbles to satisfy the highest standards

- Affordable

- Incredibly easy to use via the color Siemens touch panel

- MID (flow rate measurement), pressure and temperature sensor

- Dampable, acid and alkali resistant

- The device can be controlled directly via the filling system

Technical data:

| CARBOMAXX 20 | CARBOMAXX 40 | |

| CO2 dosing (depending on pressure, temp, flow rate*) | 0 – max. 10 g/l | 0 – max. 10 g/l |

| Flow rate | 300 – max 4.000 l/h | 300 – max 8.000 l/h |

| Max. CO2 dosing per hour | 12 kg/h | 24 kg/h |

| Accuracy CO2 dosing | +/- 0,1 g/l | +/- 0,1 g/l |

| Counterpressure at the filler | max. 8 bar | max. 8 bar |

| CO2 supply pressure | 6 – 10 bar | 6 – 10 bar |

| Max. pressure in product line in bar | 8 bar | 8 bar |

| Power supply | 230 VAC / 50 Hz | 230 VAC / 50 Hz |

| Device dimensions (H × W × D) | 70 x 45 x 25 cm | 70 x 45 x 25 cm |

| Product connections DIN 11851 | DN 25 | DN 40 |

| CO2 connection | Quick coupling | Quick coupling |

| Weight | 25 kg | 26 kg |

* The small CARBOMAXX 20 system is designed for a max. CO2 dosing of 12 kg/h. This corresponds, for example, to 6 g/l at 2,000l/h or 3 g/l at 4,000 l/h, etc. With the large CARBOMAXX 40 system, double the flow rate is possible.